When choosing drawer slides for a project, whether it's for a kitchen renovation, a tool chest, or industrial storage, a common concern is noise. Heavy-duty drawer slides are designed to withstand heavy weight and heavy use and are essential in many applications. But are they noisy? Let’s delve deeper into this topic.

Learn about heavy-duty drawer slides

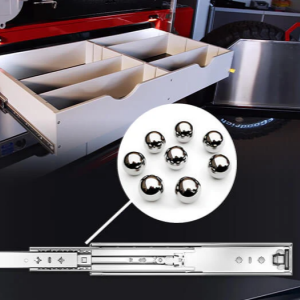

Heavy-duty drawer slides are designed to support large loads, typically 100 to 500 pounds or more. They are typically used in environments where durability and strength are critical. Examples include industrial tool boxes, commercial kitchens, and even vehicle storage. These slides are typically made from sturdy materials, such as stainless steel or high-strength aluminum, and include mechanisms such as ball bearings or rollers to promote smooth operation.

Factors causing noise

There are several factors that affect the noise level of heavy-duty drawer slides:

- Materials and Construction: The quality of materials used and construction can significantly affect noise levels. For example, metal slides may produce more noise than slides made from plastic or composite materials.

- Ball Bearings vs. Rollers: Slides with ball bearings tend to be quieter than slides with rollers. Ball bearings distribute weight more evenly for smoother operation, resulting in less noise.

- Lubrication: Proper lubrication is critical to minimizing noise. Well-lubricated rails will glide smoother and quieter. Insufficient lubrication can lead to metal-to-metal contact, which increases noise and wear.

- Installation: Proper installation ensures that the slide rails are properly aligned and securely fastened. Misaligned or loose screws can cause rattling and noise during operation.

Reduce noise

To ensure your heavy-duty drawer slides run quietly, consider these tips:

- Choose quality slides: Buy quality slides from a reputable manufacturer. Look for mentions of quiet operation in reviews or specs.

- Proper lubrication: Lubricate the slide rails regularly with an appropriate lubricant. This reduces friction and noise while extending the life of the slide.

- Accurate installation: Make sure the slide rails are installed correctly, accurately aligned and securely fastened. This helps prevent any movement or vibration that could cause noise.

- Consider a soft-closing mechanism: Some heavy-duty slides come with a soft-closing mechanism that dampens noise and prevents drawers from slamming shut.

Practical application

In actual use, many users have found that heavy-duty drawer slides do not produce excessive noise if properly maintained and installed. For example, in commercial kitchens where these slide rails are used extensively, noise levels are kept to a minimum to maintain a comfortable working environment. Likewise, in an industrial environment, while some noise is expected, well-maintained slides can help improve overall operational efficiency without causing major disruption.

in conclusion

Heavy drawer slides may make noise, but this is not an inherent characteristic. Noise levels depend on a variety of factors, including materials, lubrication and installation. By choosing high-quality slide rails, ensuring proper installation and regular lubrication, you can significantly reduce noise. For those who are particularly concerned about noise, choosing a slide with ball bearings and a soft-closing mechanism can further improve quiet operation. With the right approach, heavy-duty drawer slides can provide strength and quiet functionality in demanding environments.